No longer see the forest for the BIMming...

BIM webinars, BIM seminars for developing a BIM plan of attack, innumerable BIM libraries (1, 2, 3, 4, 5, etc.) have your products added to, BIM network events, and so on ad infinitum. BIM is so hot that you almost would think Sdu Publishers, with periodicals like Cobouw, Vastgoedmarkt, and de Architect, has changed its name to BIM Media in connection with Building Information Modelling. Exciting developments to be sure, but as a supplier to the building trade it is easy to lose your way.

Not strange that certain parties are capitalizing on that with expensive seminars to help manufacturers become completely BIM-ready and libraries manufacturers have to pay big money to be included in (e.g. BouwConnect). Fortunately, the trend is a shift towards OpenBIM. See also the article from OpenBIM-evangelist Rob Roef about the commercialism surrounding BIM.

Recently a study was published concerning the use of BIM in various European countries and what architects expect from manufacturers. The most remarkable thing to come out of the report was the finding ‘Architects expect manufacturers to make BIM information and 3D objects of their products and range available free of charge.’ How absurd! It seems to me that little research was needed to come to that conclusion.

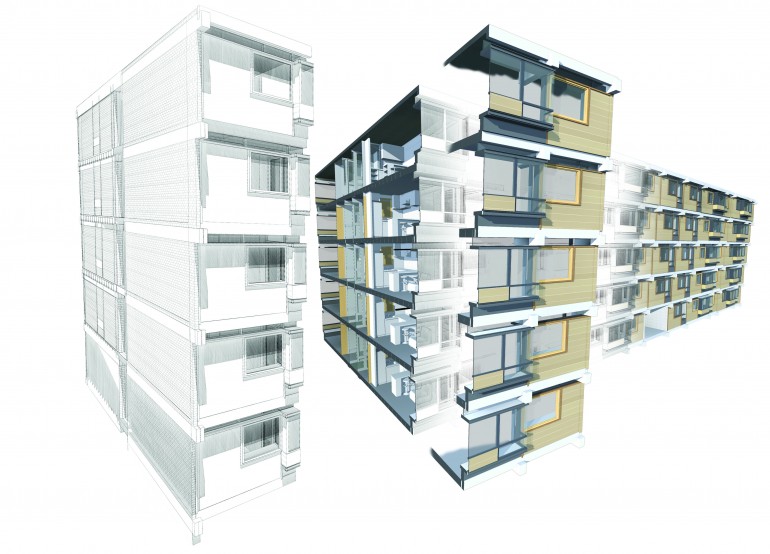

Well, in any case, there were plenty of reasons for me to conduct a little study of my own by asking BIM users what they expect from a 3D model of a roof hatch. After all, a roof hatch is not such a major part of a building. What does such a model really need to contain? And how can one ensure compatibility for everyone?

I spoke with BIM users Dennis Dudok of Hooper Architects, Martijn de Riet of MdR Advies, and Sander Malschaert (freelancer at various firms, including Kraaijvanger), all of whom provided useful information. The main thing we have to keep in mind as a manufacturer of roof hatches is to limit the information in the model, to keep the file from becoming too large. A roof hatch model should not contain much more than the major dimensions, opening direction, and connection details. Closure, handles, etc. do not have to be shown in detail. The correct model and associated specifications should be easily available for download from the website, completely preconfigured. Once implemented in one's own BIM model it must be possible to make changes, otherwise one would have to return to the supplier's website. It is also good to provide the models in IFC format, at a minimum, so they can be imported into different software packages.

These are all very useful tips, which I am going to take to heart.

What is your experience with 3D models of construction products? What do you often miss in manufacturers' models? Join the discussion on our LinkedIn page or leave your message below.

- 2026 © STAKA Bouwproducten B.V.

- PostAds

- All rights reserved.

UK

UK Nederlands

Nederlands Deutschland

Deutschland US

US La France

La France